Inspection & Life Extension

Proper maintenance of wood poles, which includes inspection and application of remedial treatments, helps add many years of safe, reliable service life to your pole plant, thereby reducing unnecessary or premature replacement costs.

Osmose pole inspection programs allow you to better manage the critical factors that determine pole performance – strength, load, and cost.

The keys to a successful wood utility pole inspection program are:

- Identifying decay & measuring defects

- Estimating the pole’s remaining strength to determine pass/fail - Inaccurate strength calculations can be costly. A false fail can lead to unnecessary spending on restoration or replacement, while a false pass can create a risk that may lead to pole failures and costly damage and repairs. Osmose technicians use StrengthCalc® software which models the cross-section of decaying poles in relation to the transverse loads. StrengthCalc accounts for both the severity and location of the decay with respect to conductors and equipment. StrengthCalc determines precise section modulus to provide the percent remaining strength for weakened poles.

- Applying effective remedial treatments to extend the safe, reliable service life of the pole. Remedial treatment is the key to getting the most out of your investment. The use of remedial treatments will earn dividends via extended pole life and improved plant resiliency.

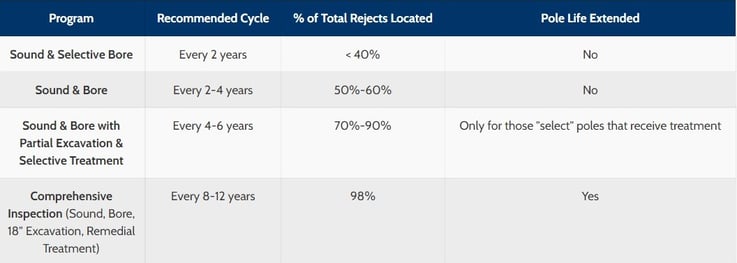

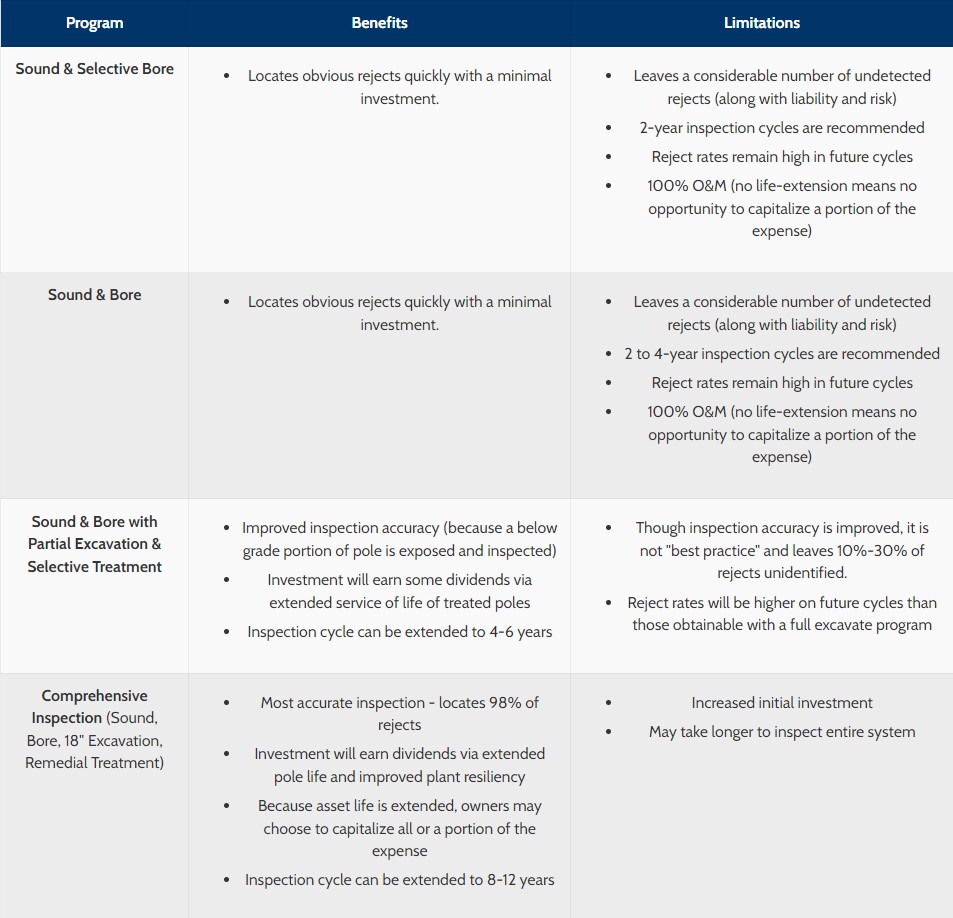

Methods & Accuracy of Wood Utility Pole Inspections

The primary purpose of a power pole inspection is to assess the wood conditions as accurately as possible. Methods vary according to the degree of wood decay and damage.- Sound and Selective Bore: Poles are "sounded" with a hammer to detect internal decay. Poles that show signs of internal decay (based on the sound test) are bored to determine the location and extent of the decay.

- Sound & Bore: Poles are "sounded" with a hammer to detect internal decay and poles are bored to determine the location and extent of the decay.

- Sound & Bore with Partial Excavation & Selective Treatment: Poles are "sounded" with a hammer to detect internal decay and bored to determine the location and extent of the decay. Poles that show signs of internal or external decay are fully excavated to a depth of 18" to determine the extent of decay at the groundline. Decayed wood is removed and a preservative paste is applied to protect the remaining sound wood.

- Industry Best Practice: Comprehensive Life Extension (sound, bore, 18" excavation, remedial treatment). Poles are "sounded" with a hammer to detect internal decay and bored to determine the location and extent of the decay. Each pole is fully excavated to a depth of 18" to determine the extent of decay at the groundline. Decayed wood is removed and a preservative paste is applied to protect the remaining sound wood.

Proper distribution pole inspection can go a long way in terms of asset improvement and cost savings. Here's the breakdown of each method and its benefits:

Selecting a Service Provider From a Myriad of Utility Pole Inspection Companies

Utility pole inspections should be handled by highly trained professionals to prevent inaccurate assessments.

Osmose has a proven track record in implementing excellent, value-adding wood pole inspection services. Every Osmose utility pole inspector is equipped to determine fungi decay and other signs of problems using a thorough utility pole maintenance and inspection process.

Wood Pole Inspection Services That Work

Efficient utility pole inspection companies understand the importance of maximizing the investment of pole plant owners. Through Osmose's wood pole inspection and maintenance process, the service and inspection lifecycle of treated poles are extended significantly. The video below details all 18 steps that make up the comprehensive power pole maintenance process.

From basic wood pole inspection to in-depth power pole repair, Osmose can help you optimize your life-extension investments by matching your program objectives with an appropriate inspection method.